Homepage Slideshow

crreglogo.png

expertsimage.png

ABOUT

Who we are and what we do...

About Cougar RED Ltd

Cougar RED Ltd formed from humble beginnings in 2005. We are now a leading precision engineering company.

Read more...CNC Milling/Turning

CNC milling and turning services including advanced 5-axis complex milling for high-technology industries.

Read more...EDM Wire Services

Complementing milling and turning capabilities, we provide EDM wire services using Agie Charmilles EDM wire technology.

Read more...Laser Marking Services

We have our own in-house laser making capability meaning we can cater for all your part marking and traceability needs.

Read more...Quality Control

We are ISO9001:2015 certified. We have temperature controlled production and inspection facilities.

Read more...CAD/CAM Technology

Leading CAD/CAM technology is deployed at Cougar RED Ltd for product design and manufacture.

Read more...showcase

Always exquisite machining...

Sample gallery images

gallery1.jpg

gallery2.jpg

gallery3.jpg

gallery4.jpg

gallery5.jpg

gallery6.jpg

gallery7.jpg

gallery8.jpg

gallery9.jpg

INNOVATION

Cougar RED makes a difference...

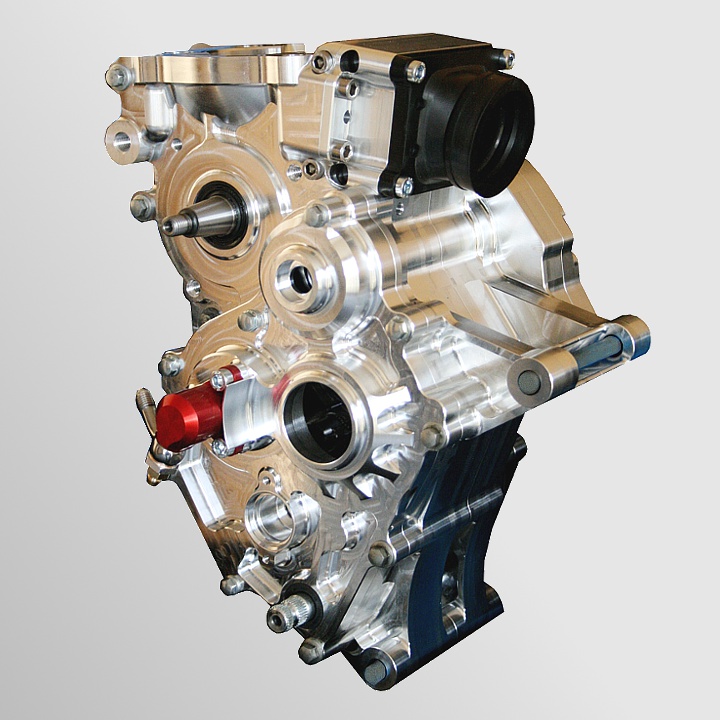

CASE STUDY 1

Lightweight Bio-ethanol engine design and manufacture.

CASE STUDY 2

Lightweight components for bicycles. High performance brake discs machined from solid.

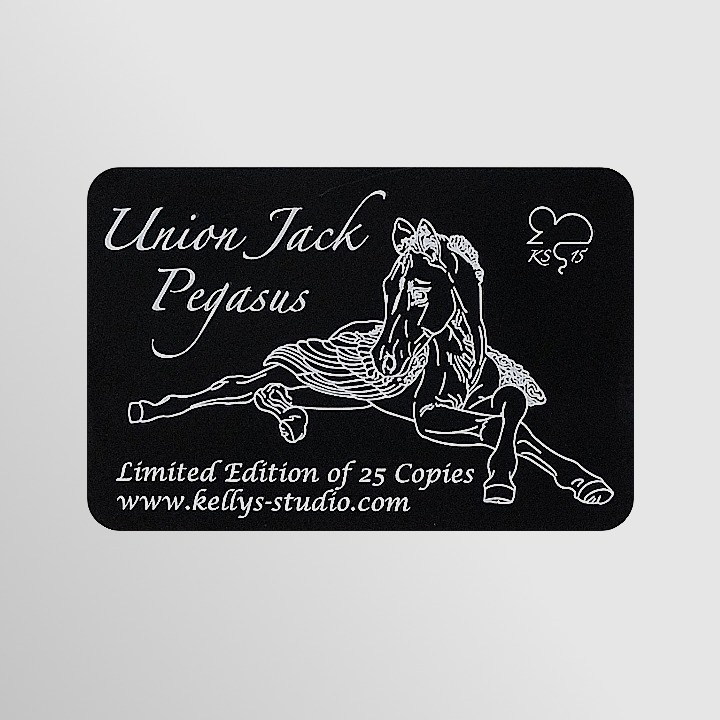

CASE STUDY 3

Specialist design and laser marking services for model horse sculptor

CASE STUDY 4

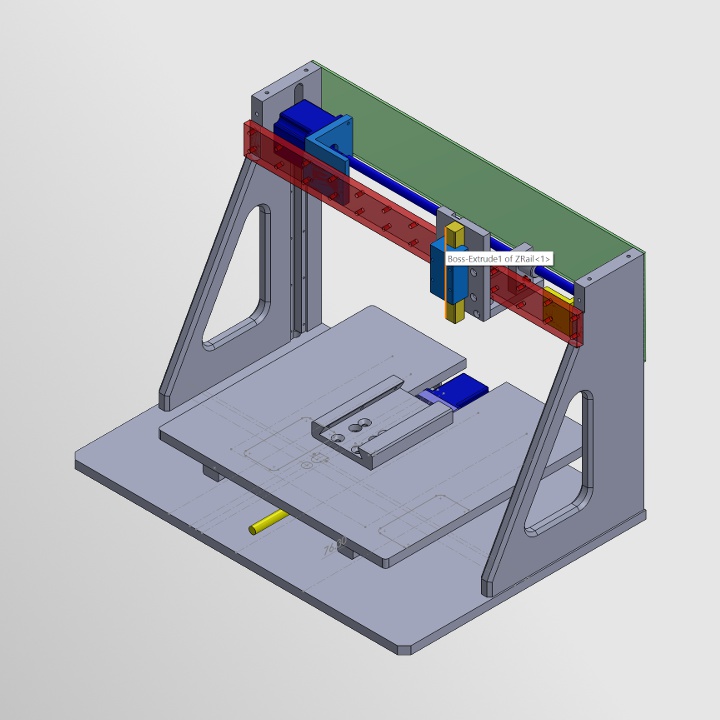

Engraving machine CAD services

CASE STUDY 5

Rockers - EDM Wire

CASE STUDY 6

Intake Trumpets - Milling & TurningContact

Like to find out more...